Vacuum Suction type Tighten Stationary

- Model

- HQ4

Item specifics

- Machine dimension

- L240*W460*H350mm

- Machine weight

- 12kg

- Screw feeding way

- Blowing and Suction

- Screw size

- M1-M6

Review

Description

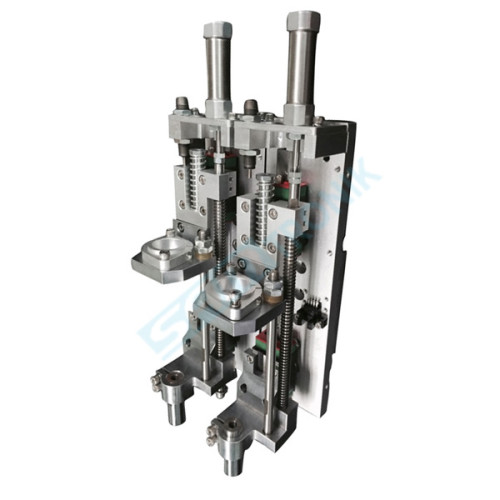

1. Tighten Stationary is a lock-and-pay module specially

designed and developed for mechanical arm and automation machine. It can be

installed on various machines. Through its internal executing mechanism, the

screw can be locked on the specified workpiece. It can be installed

independently or in multiple combinations. It can be installed vertically or

horizontally. It can be fixed on the machine or installed on the mobile arm. It

is easy to install and maintain.

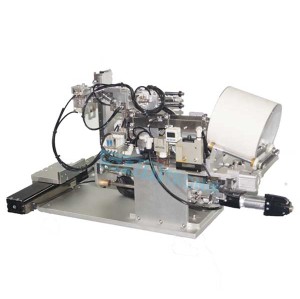

2. The locking efficiency of the lock-and-pay stationary

is high. It usually takes 1.5-1.7 seconds to lock a screw (unlike the length of

the screw, the speed of batch, the locking time will be different).

3. Lock attachment includes electric screw, servo screw

or pneumatic screw, batch knife, screw chuck, suction nozzle and cylinder,

including slideway, slider, guide rod and other guiding elements. It also

includes torsion detection, floating lock detection sensor, negative pressure

meter detection. The signals given by the sensor can be judged by PLC program

whether the screw has slider, sliding teeth, leakage lock and floating lock,

etc. Adverse phenomena and alarm prompts.

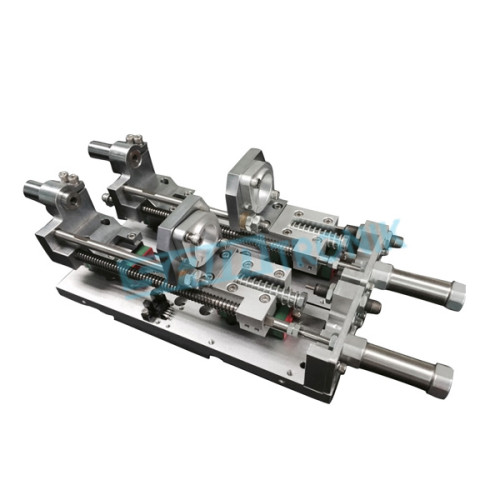

4. Through standardized design, different types of

structures can be assembled quickly to ensure the fast delivery time and spare

parts for customers. It also makes maintenance and replacement of spare parts

very simple and convenient.

Specification:

Machine construction | Machine dimension: | L240*W460*H350mm | |

Machine weight: | 12KG | ||

Air supply: | 0.4-0.6MPa | ||

Failure detection: | Floating Lock Detection (Photoelectric Inductor Detection) | ||

Electric device: | SMC | ||

type: | Blowing type | Suction type | |

Application | Screw size | M1-M6 | M1-M6 |

Screw length | 6-30mm | 2-20mm | |

Locking Torque: | 30KG | 30KG | |

Screw Ratio: | L≥1.3D (L is the total length of the screw, D is the diameter of the screw cap) | L≤1.3D (L is the total length of the screw, D is the diameter of the screw cap) | |