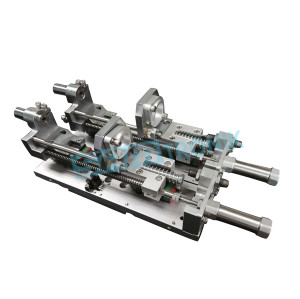

BM6-WZ Screw Tighten module

- Model

- BM6-WZ

Item specifics

- Machine dimension

- L260*W150*H700mm

- Machine weight

- 16kg

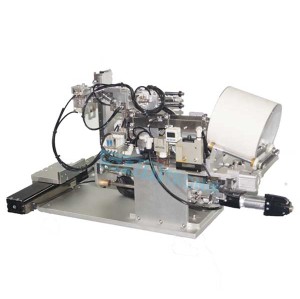

- Screw feeding way

- Blow First and Vacuum suction

- Screw size

- M1-M6

Review

Description

1. The screw is arranged by linear vibration of the drum, divided by 45 degrees oblique angle, and sent to the lock chuck under the action of air pressure. The screw should satisfy the requirement of L>1.3D (L is the total length of the screw, D is the diameter of the screw).

2. It can automatically and accurately detect the

floating lock phenomenon in the lock screw (according to the corresponding

products, it can detect the floating lock problem of 0.3-0.5mm), so there is no

need to set up special inspectors and procedures.

3. It has the function of automatically detecting whether

the feeding material is in place and whether the screw is in place. It ensures

that the screwdriver does not go down at will before locking the screw, and

ensures that the processed products are not damaged by the screwdriver.

4. The locking system is small in size and suitable for

locking with narrow space and interference around the screw hole, especially

for the combination screw with elastic flat cushion.

5. The conveying screw is blown by air pressure and the

locking device is vacuum adsorption, which can ensure that the processed

products, especially electronic products, will not be contaminated with metal

dust and dust. At the same time, because of the vacuum suction method to lock

the screw, the lock can also absorb the dust and iron chips generated during

the lock.

6. The module has Z-axis, which can arbitrarily specify

the height of the locking screw face. It is very suitable for the inconsistent

height of the product screw face. No additional Z-axis is needed to realize the

modern operation mode of product diversification.

7. To deal with high-frequency wireless communication

products or automotive electronic products, it can effectively solve the

difficulties in the industry of the location of lock-in edge, subsidence,

through-hole and the need for two displacement lock-in.

Specification: