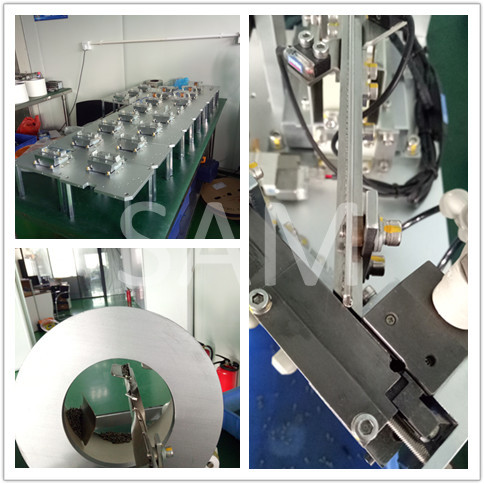

HM3 Drum Type Screw Feeder

- Model

- HM3

Item specifics

- Machine dimension

- L240*W460*H350mm

- Voltage

- AC 220V 50HZ

- Screw feeding way

- Air-blown/suction type

- Screw size

- M1--M5

Review

- N***n

- 2021/8/3 16:46

Hi

Description

Features:

1. It has simple structure, high efficiency, smooth

operation and low failure rate.

2. Using Japanese original direct vibration, it runs

smoothly and can effectively deal with the layout and material distribution of various

screw.

3. The 45 degree oblique angle is adopted to make the screw

distribution smooth and steady.

4. Roller feeding is used for screw sorting and feeding.

Intelligent screw rail feeding can effectively filter and

screen foreign bodies, iron chips and irregular screw.

5. The barrel is easy to take and place, which can be

used to clean up foreign bodies manually in time, eliminate secondary pollution

and ensure product quality.

6. Automatically detect the status of feeding screw and

timely replenish them.

7. The unique solution for combination screw;

8. Open structure is adopted, and the breakdown is clear

at a glance, and the troubleshooting is convenient and fast.

Specification:

|

Machine

construction |

Machine

dimension: |

L240*W460*H350mm |

|

Machine weight: |

12KG |

|

|

Voltage: |

AC 220V 50HZ |

|

|

Air supply: |

0.4-0.6MPa |

|

|

Temp : |

-20℃-40℃ |

|

|

Electric device: |

SMC,

KEYENCE/Panasonics Sensors, Imported Direct Vibration |

|

|

Screw feeding

way: |

Air-blown/suction

type |

|

|

Screw feeding

speed: |

60/M |

|

|

Control system(Option) |

Main control

program |

Singlechip |

|

I/O Signal |

4 INPUT/2

OUTPUTS |

|

|

Application |

Screw size |

M1--M5 |

|

Screw length |

6-30mm |

|

|

Barrel capacity: |

1200PCS(M5*16mm as

sample) |

|

|

Screw Ratio: |

Blow-in type: L

> 1.3D (L is the total length of the screw, D is the diameter of the screw

cap) |