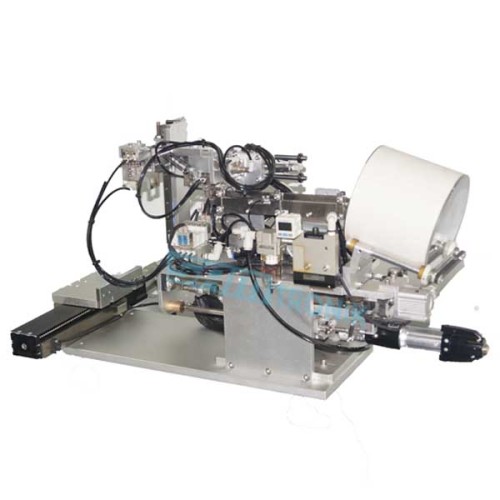

BM6-H Screw Tighten module

- Model

- BM6-H

Item specifics

- Machine dimension

- L160*W320*H780mm

- Machine weight

- 22kg

- Screw feeding way

- Clamping flip + vacuum suction

- Screw size

- M1-M4

Review

Description

1.Screws

feeding from drum through screening chute rail , linear vibration to the

screwdriver position (eliminate the material secondly pollution caused brush

and other consumable materials). For long and short screw diameter, specific

screw head or with elastic gasket flat pad, square tile, gaskets and other

special shaped screws, could smooth feeding.

2. Automatically and accurately detect the

floating lock phenomenon (according to

the corresponding product, can detect 0.3-0.5mm floating lock problem ), so

there is no need to arrange a special testing worker and procedures .

3.Machine with automatically detecting

whether feeding material is in place, and whether it has screw or not function

,make sure that the screwdriver won’t

move down before screw tighten action, so as to ensure that the

processed product is not damaged by the screwdriver bits.

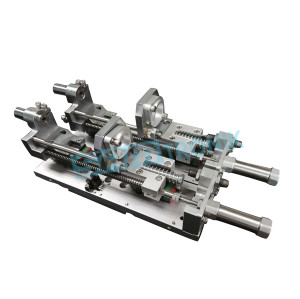

4.The feeding system and the screwdriver part

are integrated and modularize, which is suitable for high precision screw

tighten request and stable automatic integration equipment environment

requirement.

5.Screws with negative pressure adsorption

and through filter during tighten process, guarantee the processed products

especially electronic products is not contaminated with metal powder and dust.

At the same time, vacuum suction fix and tighten screws method , can absorb

dust and iron powder on screw.

6. Module with

Z axis, can arbitrarily specify the height of locking screw face, extremely

suitable for products where the height of screw face is inconsistent, so as to

realize the modern operation mode of product diversification; especially

suitable for large-scale automation integration projects.

7. Professional development for horizontal

locking, effective solution technology Technical difficulties, void the

secondary positioning offset and design cost caused by product turnover,

effectively improve

manufacturing efficiency, improve quality and

reduce costs.

Specification:

|

Machine |

Machine

dimension: |

L160*W320*H780mm |

|

Machine

weight: |

22kg |

|

|

Voltage: |

AC 220V 50HZ |

|

|

Air

supply: |

0.4-0.6 MPa |

|

|

Temp : |

-20℃-40℃ |

|

|

Electric

device: |

SMC&ADEC&CKD

Pneumatic Component+KEYENCE Sensor+Panasonic Motor+ THK

Cylinder/Rodless Cylinder |

|

|

Screw feeding

way: |

Clamping flip + vacuum suction |

|

|

Screw stroke: |

145(245)st |

|

|

Control

system(Option) |

Main control program |

PLC Control |

|

HMI |

Touch screen |

|

|

Program input |

Coordinate input |

|

|

I/O Signal |

32 INPUT/ 28

OUTPUTS |

|

|

Communication |

Serial port

RS232C |

|

|

Program storage |

30 group

(according to customer request edit program,program free switch) |

|

|

Screwdriver |

Brand |

Japan

HIOS screw driver |

|

Torque |

Adjustable (depends on customer

request ) |

|

|

Application |

Screw size |

M1-M4 |

|

Screw length |

2-30mm |

|

|

Screw type |

All type screws |

|

|

Detection |

Screw slip

detection |

Yes |

|

Screw float

detection |

Yes |

|

|

Screw leakage

detection |

Yes |

|

|

NG Screw tighen

detection |

Alarm light +

buzzer on |